Upgrade the equipment you already own

We understand that sometimes the best machine you can have, is the one without payments. This doesn’t mean you should have to settle for less performance though. Outfit your current machine with these accessories and save time & money, while increasing your performance.

Optimize Your Time, and Your Seedbed

With the Optimizer Basket™ on your strip-till machine, you no longer have to choose between adjusting your baskets, or staying in the cab covering more acres.

Admit it...

If it’s hard to adjust, you’re not going to do it as often as you should. Many strip till machines on the market today have time consuming, cumbersome, knuckle-busting spring adjustments. The Optimizer Basket™ puts seedbed control at your fingertips so you can optimize your seedbed no matter the conditions.

Don't stop, adjust on the fly

Easily adapt to varying soil types and conditions quickly with in-cab, adjustable, pneumatic down pressure. The Optimizer Basket™ puts on-the-go control in your hands… without a wrench & from the cab.

Have it Your Way

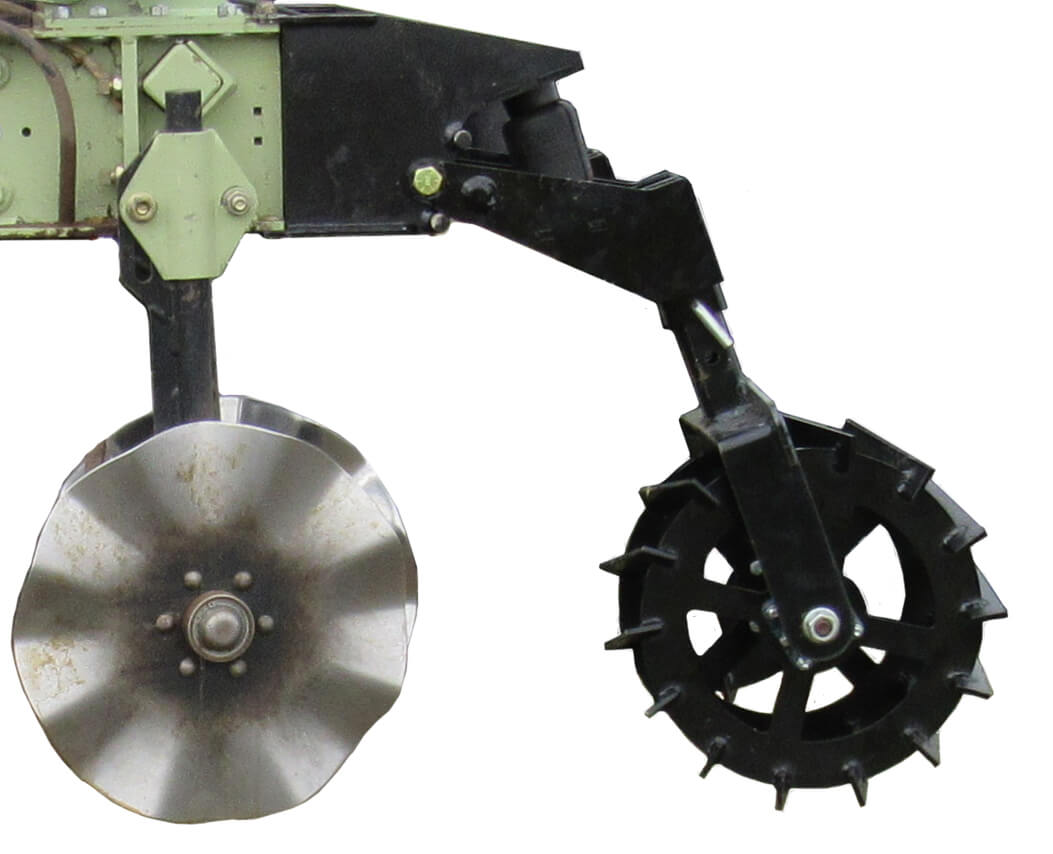

Not all soils are created equal, and the one-size-fits-all approach from OEM’s doesn’t begin to fit all your needs. The Optimizer is now available with three different finishing options to allow you to tailor your finish to your field.

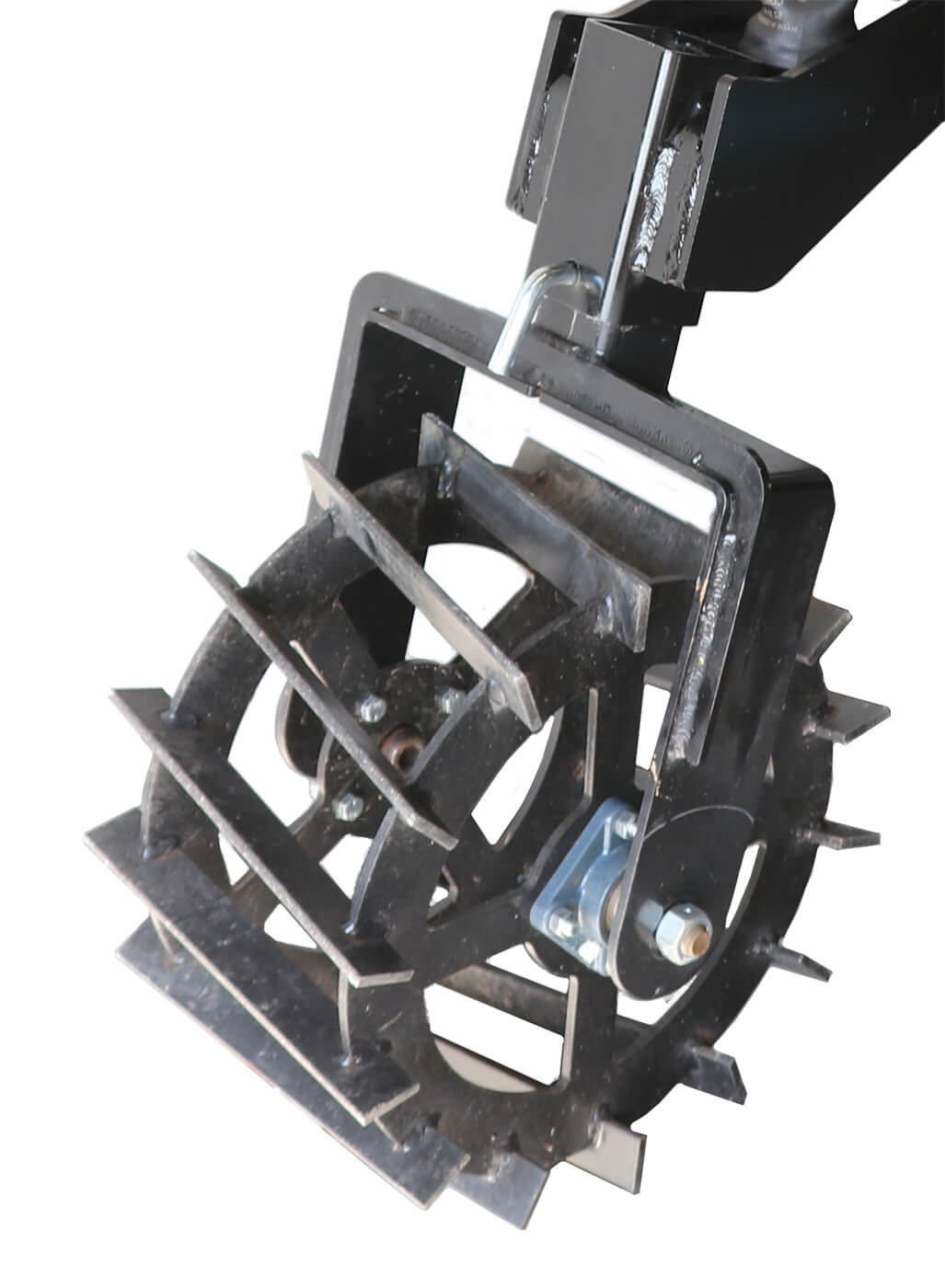

Stop Plugging, Keep Rolling

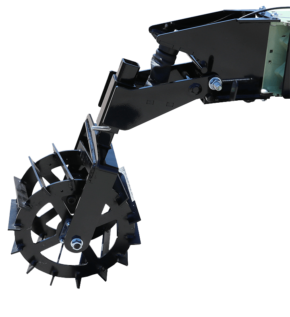

The Optimizer Baskets’ 16″ diameter cleated baskets are engineered with an open center design to reduce plugging in wet conditions and to keep you stripping.

Firm the Soil, Seal in Moisture

Sandy soils and dry conditions can be tricky to manage in strip-till. The Rubber Press Wheel option helps to firm the strip and seal in moisture, giving you a great seedbed with increased moisture to help in germination.

Mulch, Shed & Firm Your Strip

Tough & sticky soils create their own set of challenges for most strip-till baskets on the market, causing them to plug or leaving behind a rumble strip with their horizontal basket bars. The Steel Wheel option gives a better mulch effect with many points of contact, and easily sheds mud, while still firming the soil.

Pull the pin, and slide it in

Most of the time, covering more acres means traveling further distances to fields and larger changes in topography or soil types. With the Optimizer, you can quickly and easily pull the pin and slide in a new attachment to meet these changes in a matter of minutes. Eliminate the limitations of your current machine and quickly adapt to create the best seedbed possible.

- Orthman 1tRIPr™

- Bigham Strip-till

- Don’t see what you need?

- Call 1-308-708-8185 or Email, and we will look at options we can offer to fit your machine.

Forward Thinking

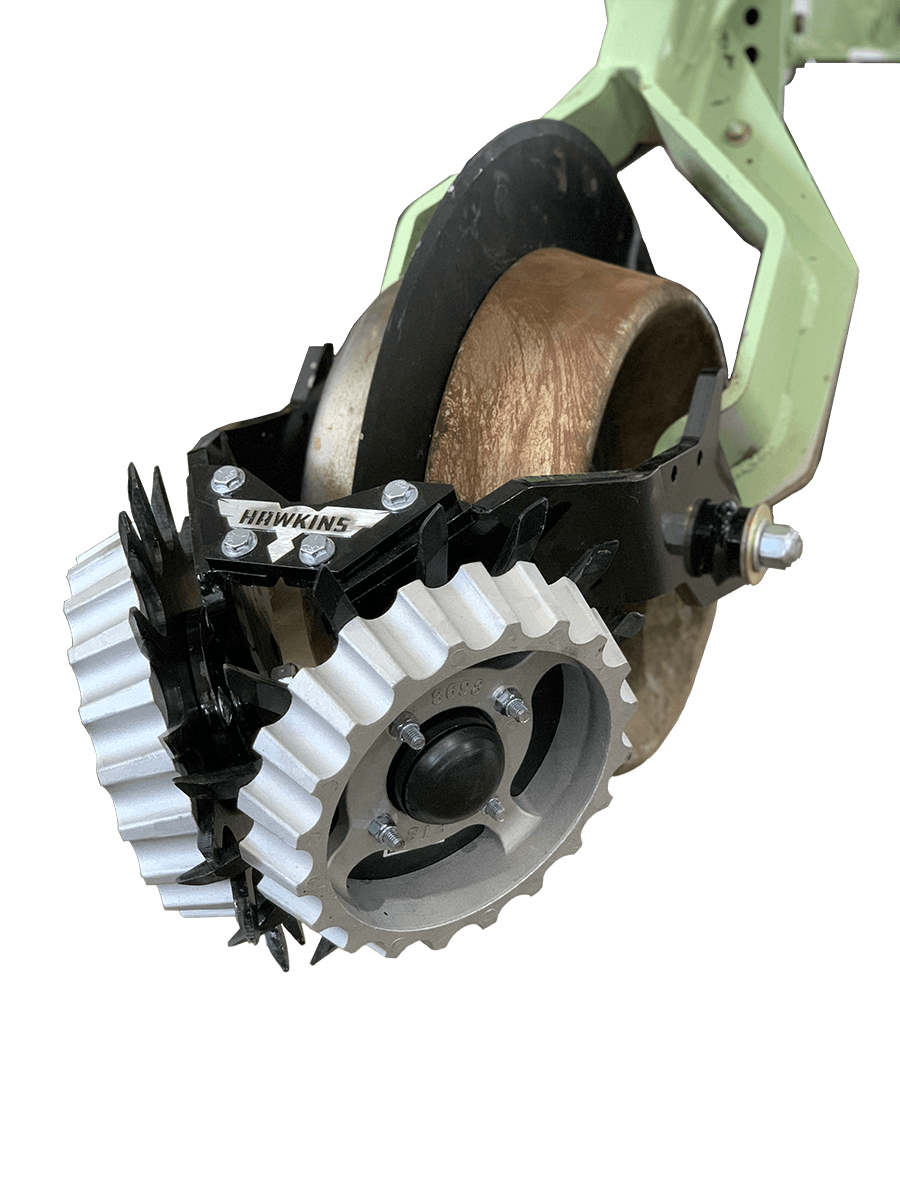

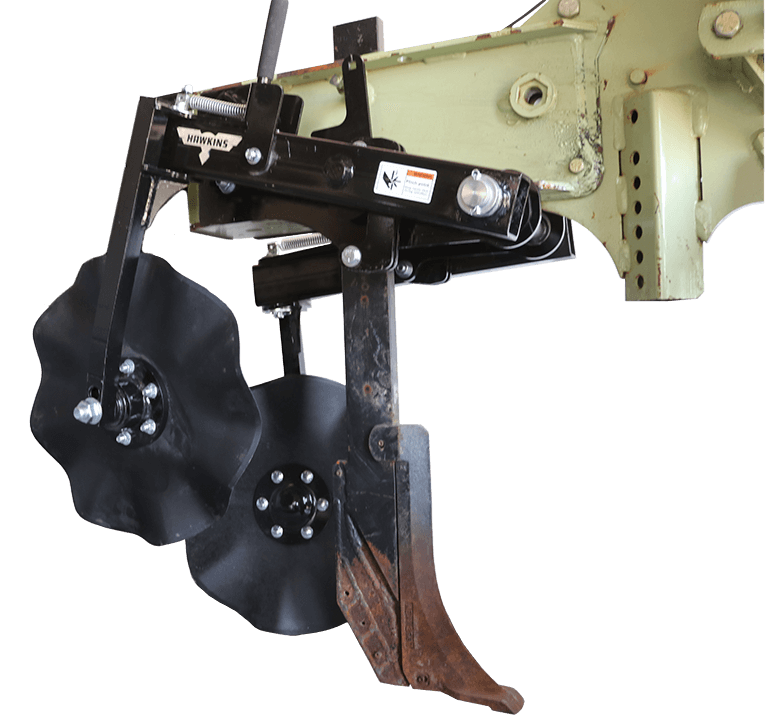

Upgrading your strip-till machines’ row cleaners with the Trailblazer™-STO before next season may be the best decision you make in the off-season. Do the work up front, you’ll be glad you did.

Move Forward

Poor residue management is costly. Problems like poor emergence due to residue and rootballs being smashed into the strip by depth band coulters are all avoidable with the Trailblazer™-STO floating row cleaners for your strip till machine.

Hands-Free

The Trailblazer™-STO automatically adjusts to contours and conditions in your fields, eliminating the need to adjust field to field, keeping you in the cab and covering acres.

Out with the old

Once you pull the pin and remove your old row cleaners, you are less than 15 minutes away from having the Trailblazer™-STO installed. The intelligent design uses common pivot points and the fit-up is as good, if not better, than factory.

Take it Head On

The Trailblazer™-STO is built to handle the roughest conditions you can push it into. The finger tooth residue managers and depth wheels are mounted on dual sealed bearings that require zero daily maintenance or greasing.

- Orthman 1tRIPr

- Don’t see what you need?

- Call 1-308-708-8185 or Email, and we will look at options we can offer to fit your machine.

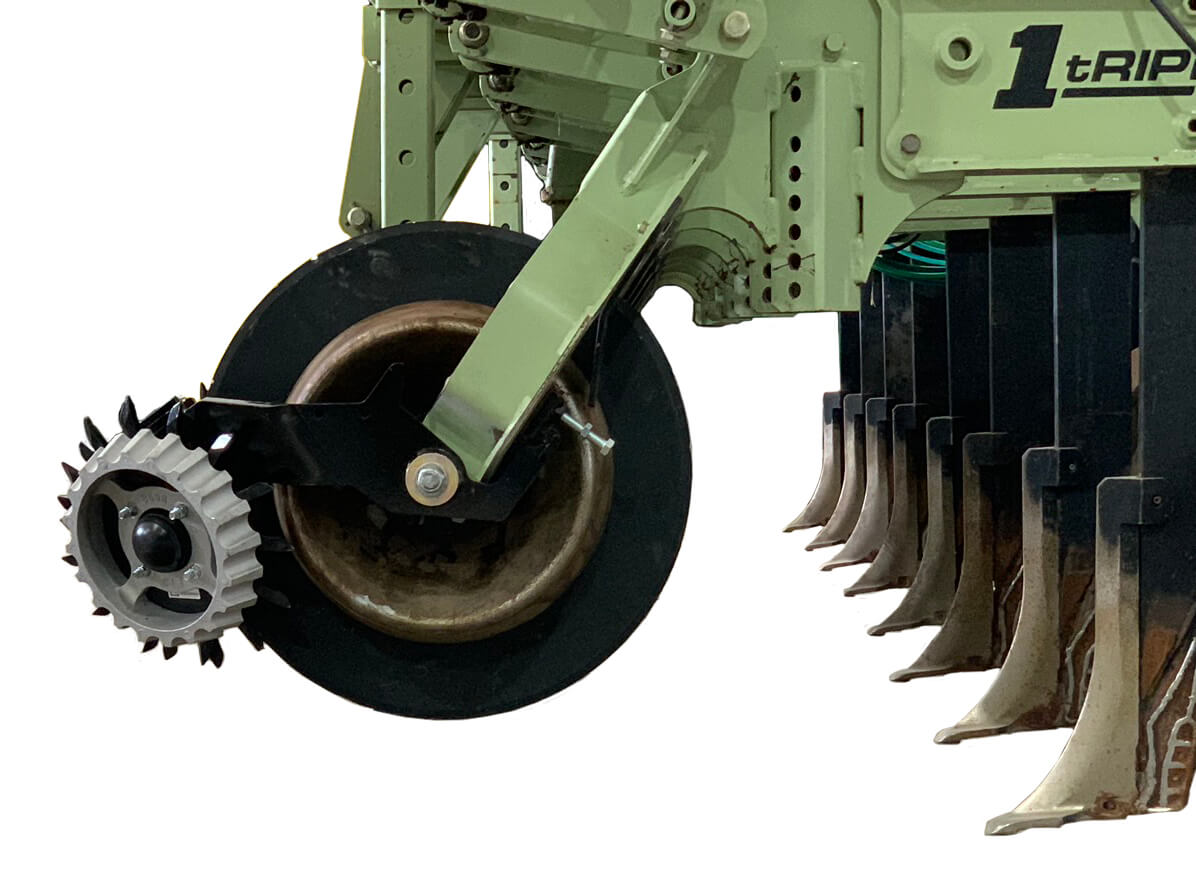

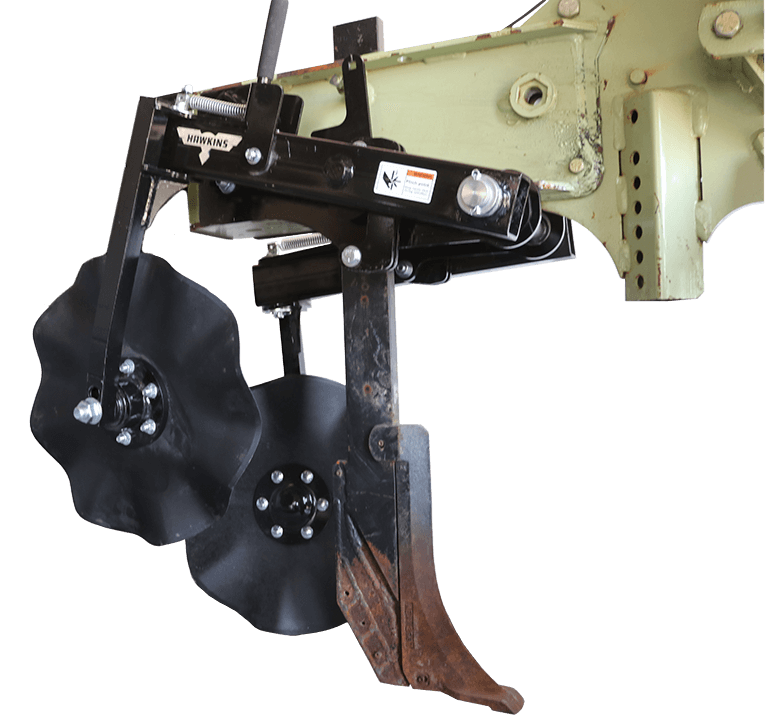

Eliminate your limitations

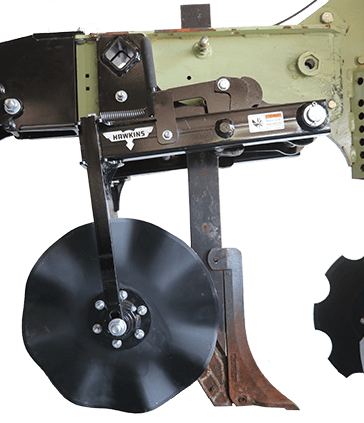

Creating your ideal seedbed is something that is defined by you, so stop letting your current machine’s limitations hold you up. Upgrading your strip-till machines’ berm coulters with the FlexBerm™ Conditioning System gives you simple, wrench-free angle and depth adjustment so you can quickly and easily set your machine to build the perfect berm for your conditions.

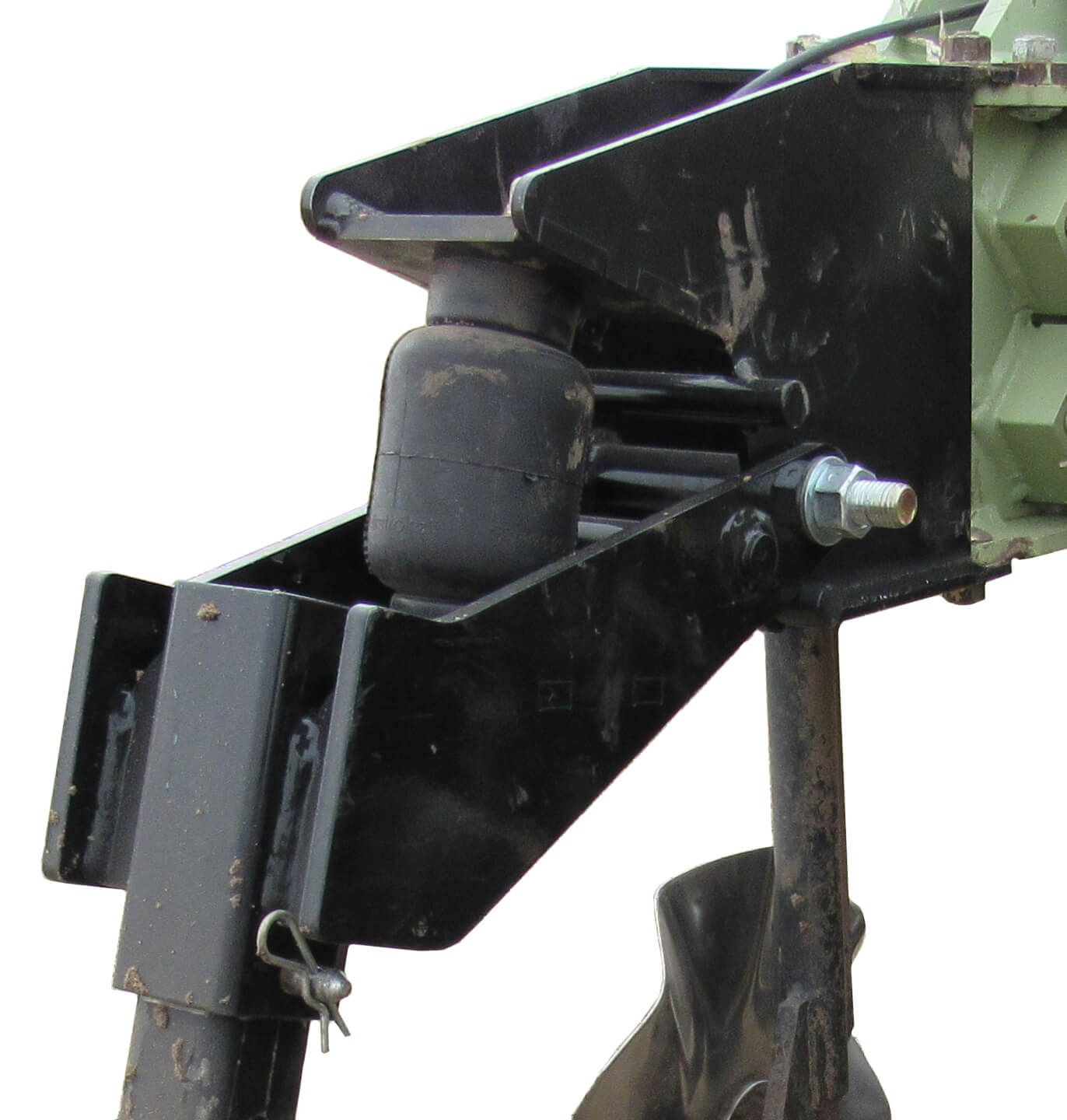

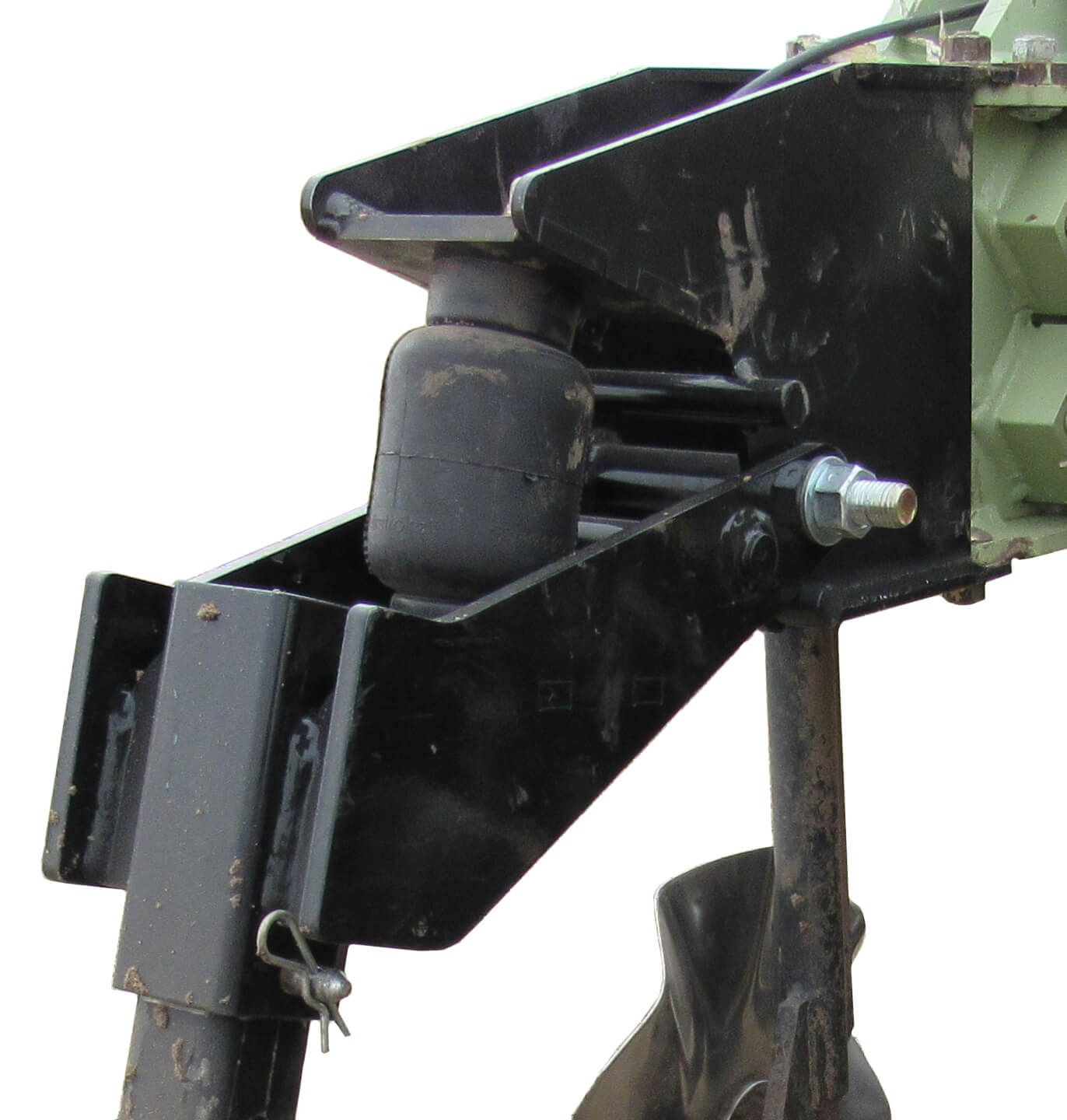

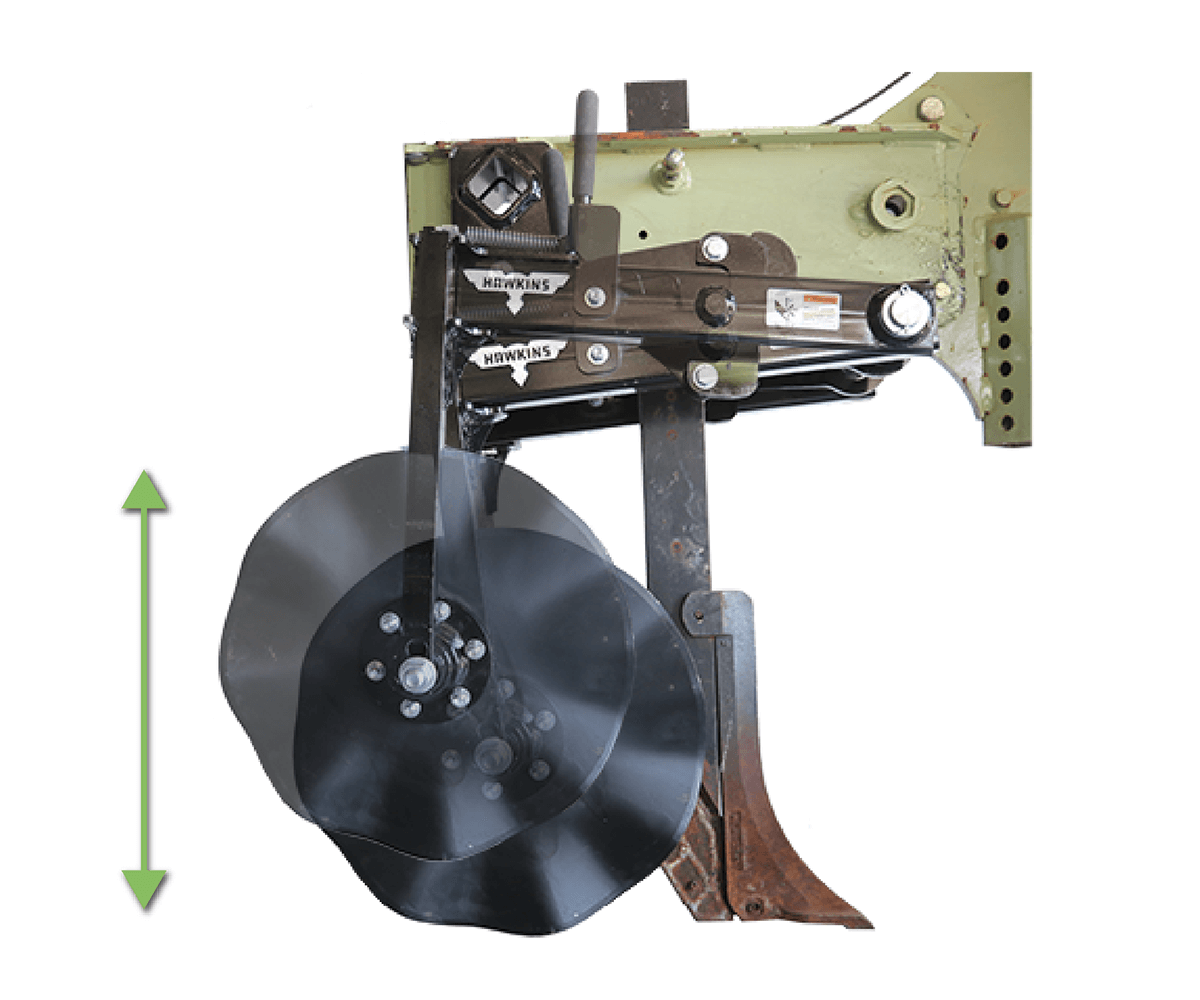

Float-on or Dig-in

With the simple, wrench-free depth adjustment handle, you can quickly set your float limit setting. This makes it quick and simple to make depth adjustments as your operating conditions change. Better yet, you don’t have to struggle with corroded set screws, wrenches and a tape measure anymore.

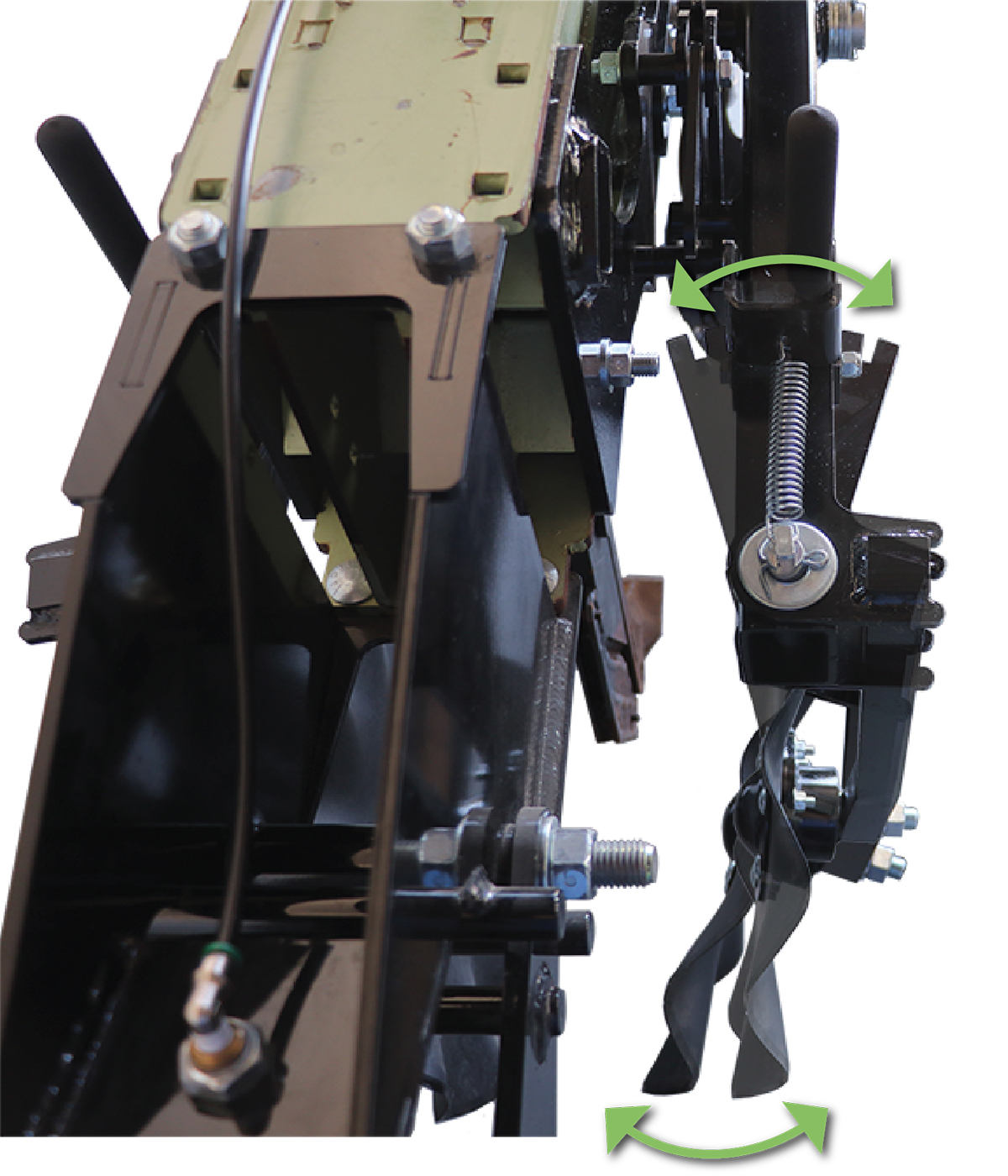

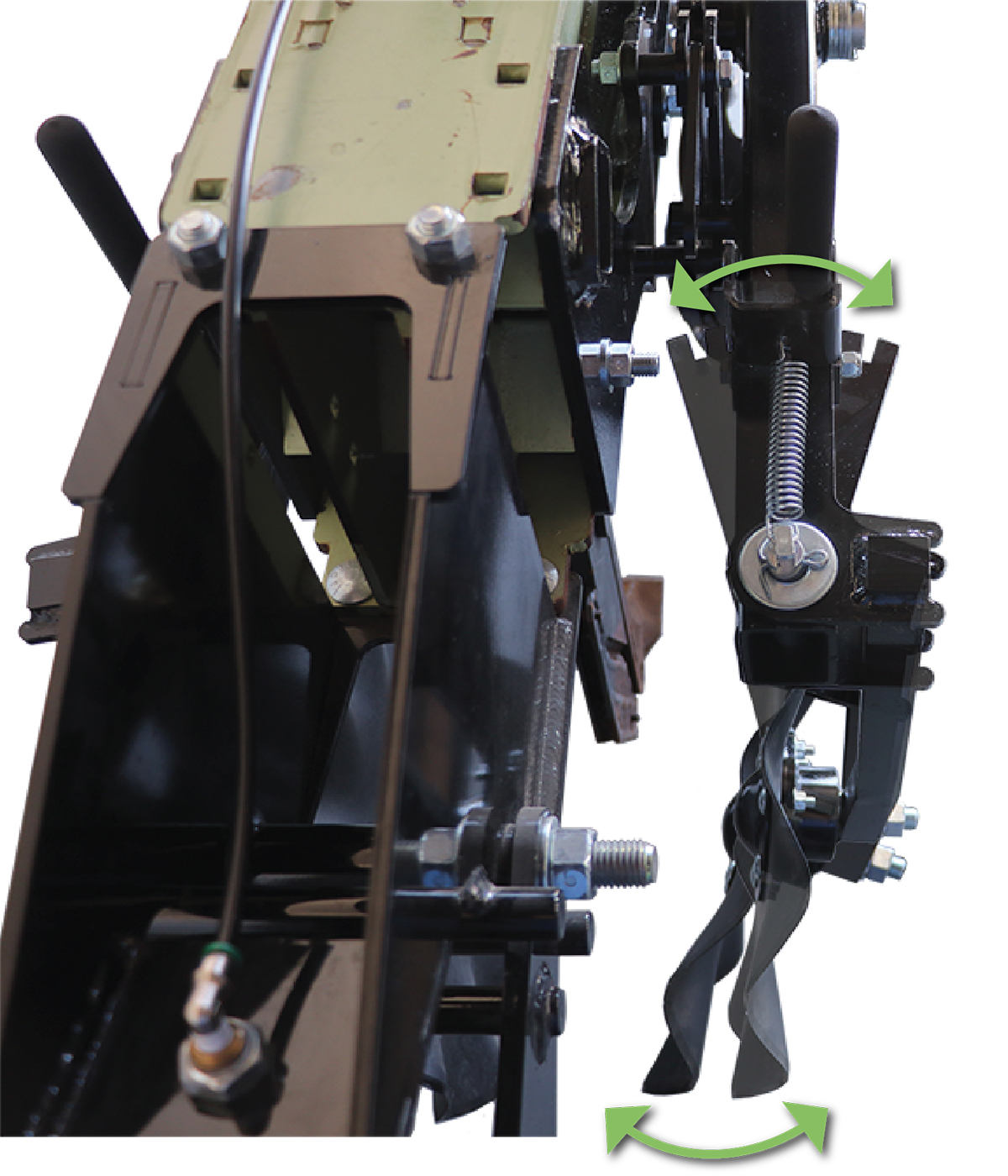

What's Your Angle?

We think you know what’s best when it comes to setting up your perfect berm, and factory non-angle adjustable blades just don’t cut it. The wrench-free, easy-to-adjust, 18″ FlexBerm™ blades are angle adjustable from 2° – 18° and allow you to choose what’s best for your berm building.

Flow on Through

The blade support arms on the FlexBerm™ are mounted on the outside of the coulters, creating a wide-open area for soil mixing and blending between your coulters without large obstructions blocking the soil flow through your units.

Lock-It-Up

Driving out worn roll pins to replace points and adjust fertilizer depths are hard enough without a big sharp coulter in the way. With the simple lock-up position on the depth adjustment handle, lock the blade up and out of your way while hammering away at those roll pins.

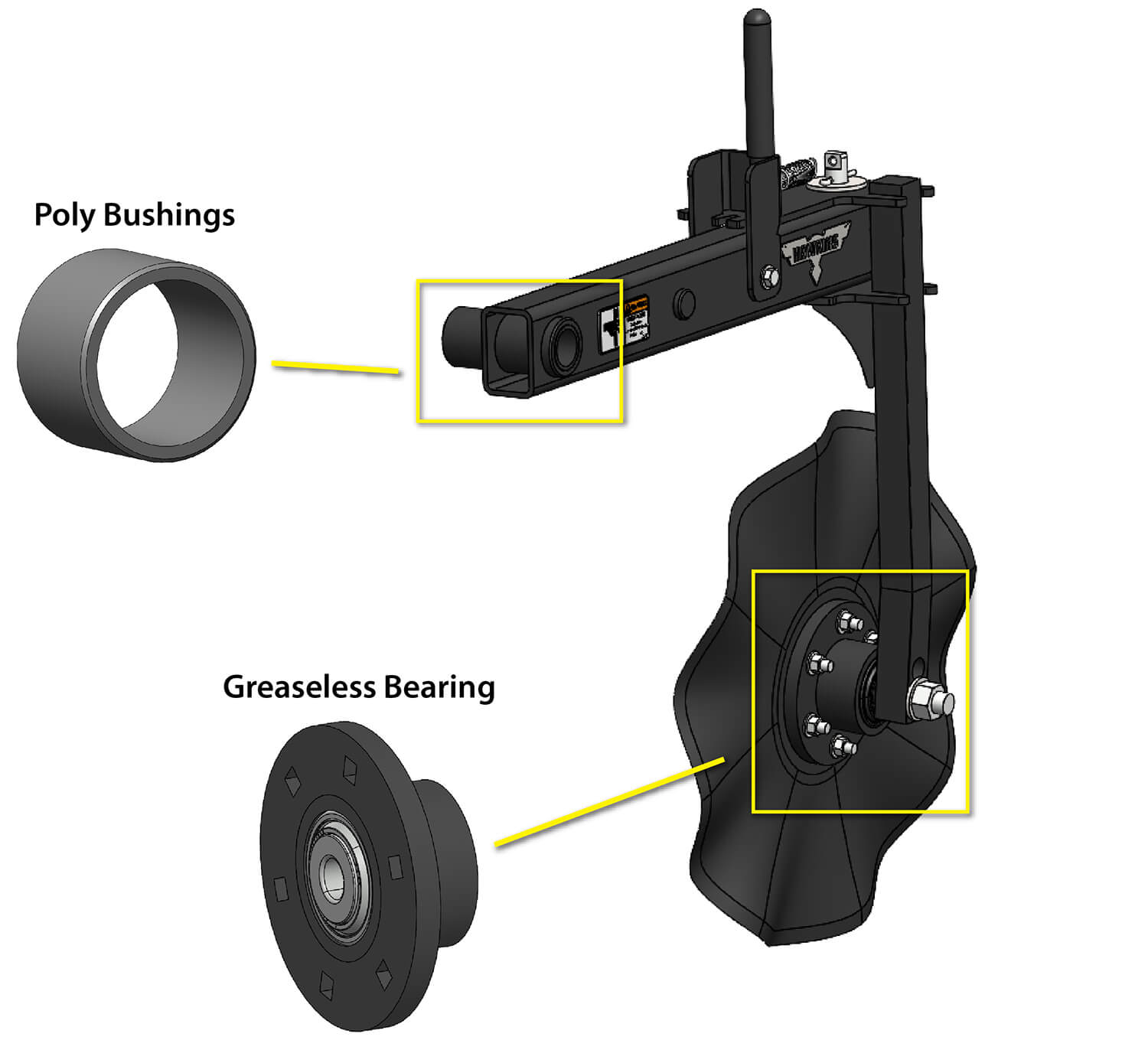

No Maintenance

The FlexBerm™ is built to handle the roughest conditions you can put it in. The 18″ Wavy Coulters are mounted on heavy-duty hubs with two sealed bearings, and the arms pivot on greaseless bushings requiring zero daily maintenance or greasing.

Out with the Old

Once you break your old wavy coulters loose, you are less than fifteen minutes away from having the FlexBerm™ installed. The intelligent design uses common mounting points and the fit-up is as good, if not better than factory.

- Orthman 1tRIPr

- Don’t see what you need?

- Call 1-308-708-8185 or Email, and we will look at options we can offer to fit your machine.